Engineering & Quality Control

Engineering

Pennant’s Engineering Team provides innovative and cost-effective solutions for customers’ metal forming requirements. Our team keeps on the forefront of new technologies, is client-dedicated, and upholds the highest professional standards in the field of metal forming engineering. From initial project conception, launch, and ongoing manufacture, our Engineering Team remains engaged and responsive to our customers’ needs. Our “Innovation Team” is on constant lookout for projects to enhance value for existing operations and parts

Comprehensive Project Management

- Expertise in both external and internal project management.

- Seamless handling of new product launches and takeover projects.

- Full lifecycle support: initial review, design phase, implementation, and quality production.

- Proven track record in delivering projects on time and with precision.

Cost-Effective Metal Forming Solutions

- In-house analysis of potential parts for the most cost-effective production methods.

- One-stop-shop for metal forming solutions to streamline your manufacturing process.

Collaborative Engineering Expertise

- Close collaboration with customers to develop high-quality parts and efficient production processes.

- Hands-on involvement in design and manufacturing phases to identify and resolve issues pre-launch.

Internal Manufacturing Support

- Internal project management for resource utilization, time management, and quality control.

- Ensures the best cost-benefit for customers through optimized internal processes.

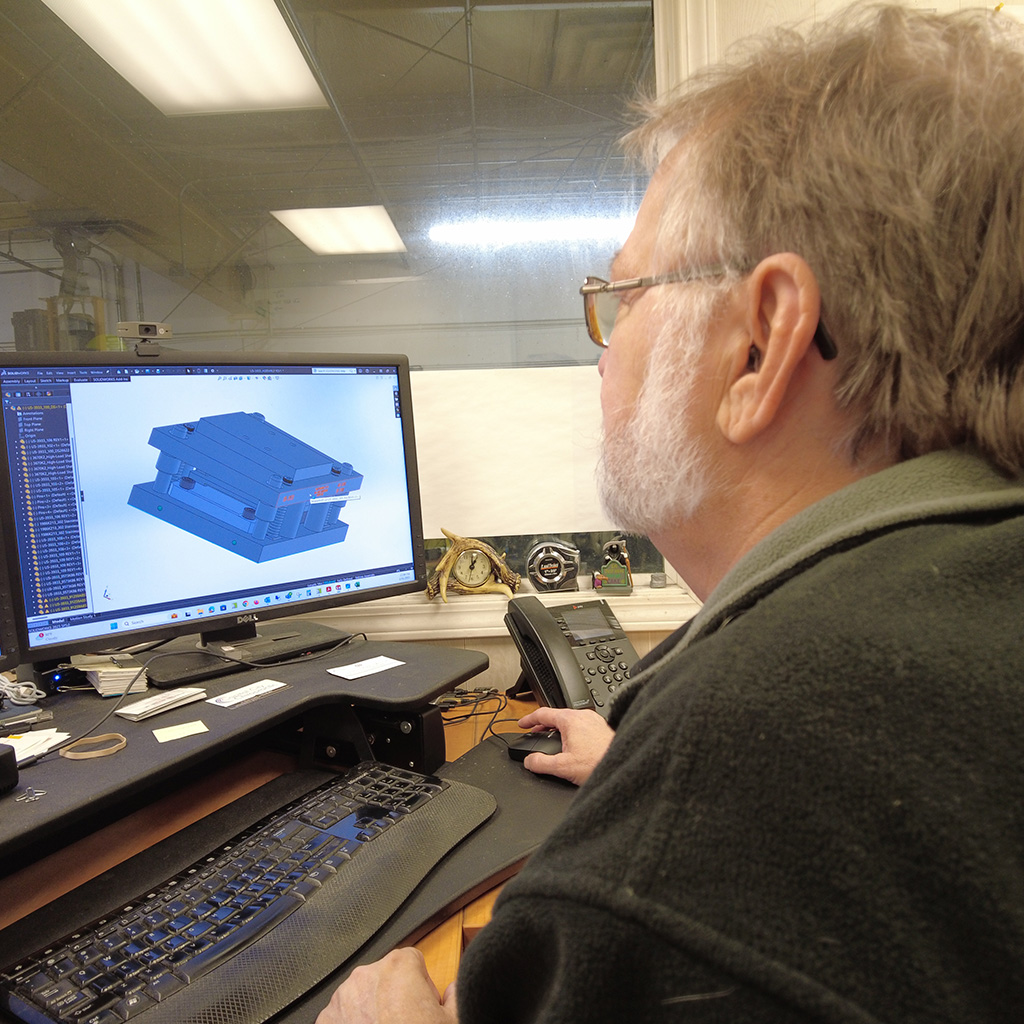

Advanced Engineering Tools

- Utilization of CAD (2D and 3D), IGES, STP, and DXF files for seamless idea-to-part translation.

- Capability to transform customer data into fully realized products with precision and reliability.

Quality Control

As a high-quality metal stamping manufacturer, Pennant Moldings Inc. is committed to quality assurance. From top management through every department, outstanding quality is our highest priority. All employees are focused on supplying our customers with quality parts at each step of the metal fabrication process. We work with our customers to maximize their satisfaction with our quality systems and procedures and to achieve continuous improvement of our products and services.

Commitment to Quality Standards

- Adheres strictly to ISO 9001:2008 quality management guidelines.

- Regular audits, staff training, and system upgrades ensure continuous improvement.

Advanced Process Control

- Utilizes statistical process control (SPC) to meet and maintain customer specifications.

- Ensures all parts and components are within tight tolerances.

Empowered Quality Control Team

- Team members are authorized to withhold shipment of any lot that does not meet customer specifications.

- Responsibility and authority to enforce strict quality standards.

Customer-Centric Goal

- Strives for a 100% acceptance rate by customers.

- Ensures parts consistently meet or exceed expectations.