Assembly

Assembly

At Pennant, we specialize in delivering comprehensive manufacturing assembly solutions tailored to meet the diverse needs of multiple industries, including automotive, solar, home appliances, agriculture, and more. Our advanced assembly processes are designed to enhance efficiency, reduce production time, and ensure the highest quality standards.

Precision Assembly Solutions for Every Project

Pennant utilizes a variety of assembly techniques to meet the specific requirements of each project:

- Mechanical Assembly: Combining components using fasteners, screws, and rivets for robust and reliable product construction.

- Welding Assembly: Advanced robotic and manual welding techniques ensure strong, durable joints suitable for heavy-duty applications.

- Adhesive Bonding: High-strength adhesives provide seamless bonding for materials where traditional fasteners are not suitable.

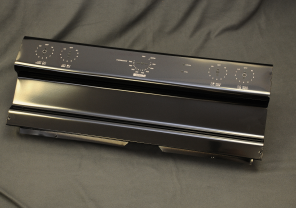

- Electrical Assembly: Precision wiring and electronic component integration for complex systems, ensuring operational reliability.

- Sub-Assembly: Modular assembly processes that streamline final production and improve flexibility.

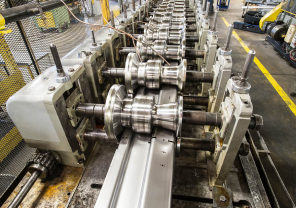

- Automated Assembly: Utilizing cutting-edge automation technologies to increase production speed, consistency, and cost-efficiency.

Precision Assembly Solutions for Every Industry

Pennant proudly serves a wide range of industries, providing specialized assembly solutions that meet unique industry demands:

- Appliances: Reliable and aesthetically pleasing assemblies for consumer products.

- Building Products: Complex structural assemblies designed for large-scale engineering projects.

- Heavy Truck: Precision assemblies for critical vehicle components, ensuring safety and performance.

- Industrial: Advanced assembly capabilities for simple sub-assemblies or complex, multi-component systems, Pennant has the expertise and resources to deliver.

- Lawn & Garden: Heavy-duty assemblies built for durability and long-term performance in rugged environments.

- Utilities: Durable assemblies for solar panel infrastructures designed to withstand harsh environmental conditions.

Benefits of Pennant’s Assembly Services

Partnering with Pennant for your manufacturing assembly needs offers numerous advantages:

- Improved Efficiency: Streamlined processes reduce production time and operational costs.

- Enhanced Quality Control: Rigorous inspection protocols ensure each product meets stringent quality standards.

- Scalability: Flexible assembly solutions adapt to projects of all sizes, from small components to large-scale assemblies.

- Cost-Effectiveness: Optimized workflows and automation reduce labor costs and material waste.

- Custom Solutions: Tailored assembly processes to meet specific industry and product requirements.

Other Services

Fabrication

Pennant provides precision metal fabrication solutions tailored to meet diverse…