Roll Forming

Roll Forming

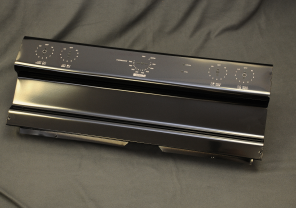

Pennant’s roll forming expertise enables us to deliver custom metal profiles across a range of industries, from automotive and heavy-duty trucking to solar and construction. Our advanced roll forming processes produce consistent, high-strength components designed for durability and precision. We meet diverse industry specifications, crafting solutions tailored to both structural and aesthetic needs.

Precision Roll Forming Solutions for Complex Production Needs

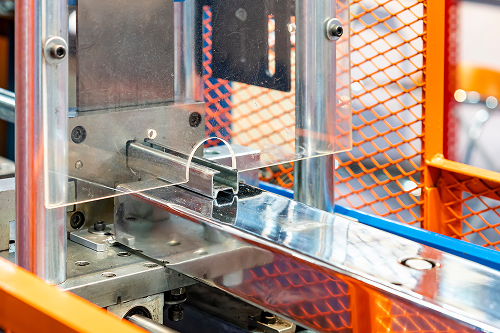

- Advanced Technology: Over two dozen advanced roll forming lines with 8 to 29 forming passes for precision shaping.

- Pre-Notch and Cut-Off Capabilities: Ensures superior accuracy and customization for complex production requirements.

- Integrated Forming Technology: Advanced combo press brake and roll form line merges continuous roll forming with precision brake forming in a single, streamlined system—reducing secondary handling and improving dimensional consistency across complex profiles.

- Material Versatility: Works with a variety of metals, including: Pre-Coated materials, Decorative stainless steel, aluminum, and galvanized steel.

- Dimensional Flexibility: Roll formed capabilities in widths over 30 inches and lengths up to 40 feet with depths reaching .375 inches (9.5 mm).

- Efficient and Scalable Production: Delivers large-scale efficiency while maintaining fine detail and quality in components.

- Trusted Partner: Known for meeting the highest standards in complex manufacturing demands.

Added Value Services

Alongside roll forming, we provide integrateds value-added services, including robotic welding, custom finishing, assembly, and quality inspection, ensuring that every component meets stringent quality standards. Pennant’s commitment to end-to-end manufacturing efficiency supports seamless production and assembly for our clients, reducing costs and optimizing lead times.

Other Services

Fabrication

Pennant provides precision metal fabrication solutions tailored to meet diverse…